What to Know About Coping Trim

No matter if you’re working on new construction or remodeling, you will rarely find two walls that are at an absolute 90-degree angle. So getting two 45-degree miters to meet perfectly tight in a corner can be frustrating, especially if the molding you’re trying to miter has an intricate profile.

The secret for tight-fitting trim on inside corners is coping the joint. Carpenters have been using this foolproof technique for years. It involves cutting the profile on the end of one molding and fitting it against another, like pieces of a puzzle.

In a coped baseboard corner, one molding has a square cut on the end that butts up against the adjacent wall. The other molding fits perfectly against the face of the first molding by cutting the end to follow the profile of the first molding.

You only need a few tools for this job: a coping saw, a miter saw, and a round file. It’s always nice to have a few sharp coping saw blades on hand. Sandpaper is handy to fine-tune your work.

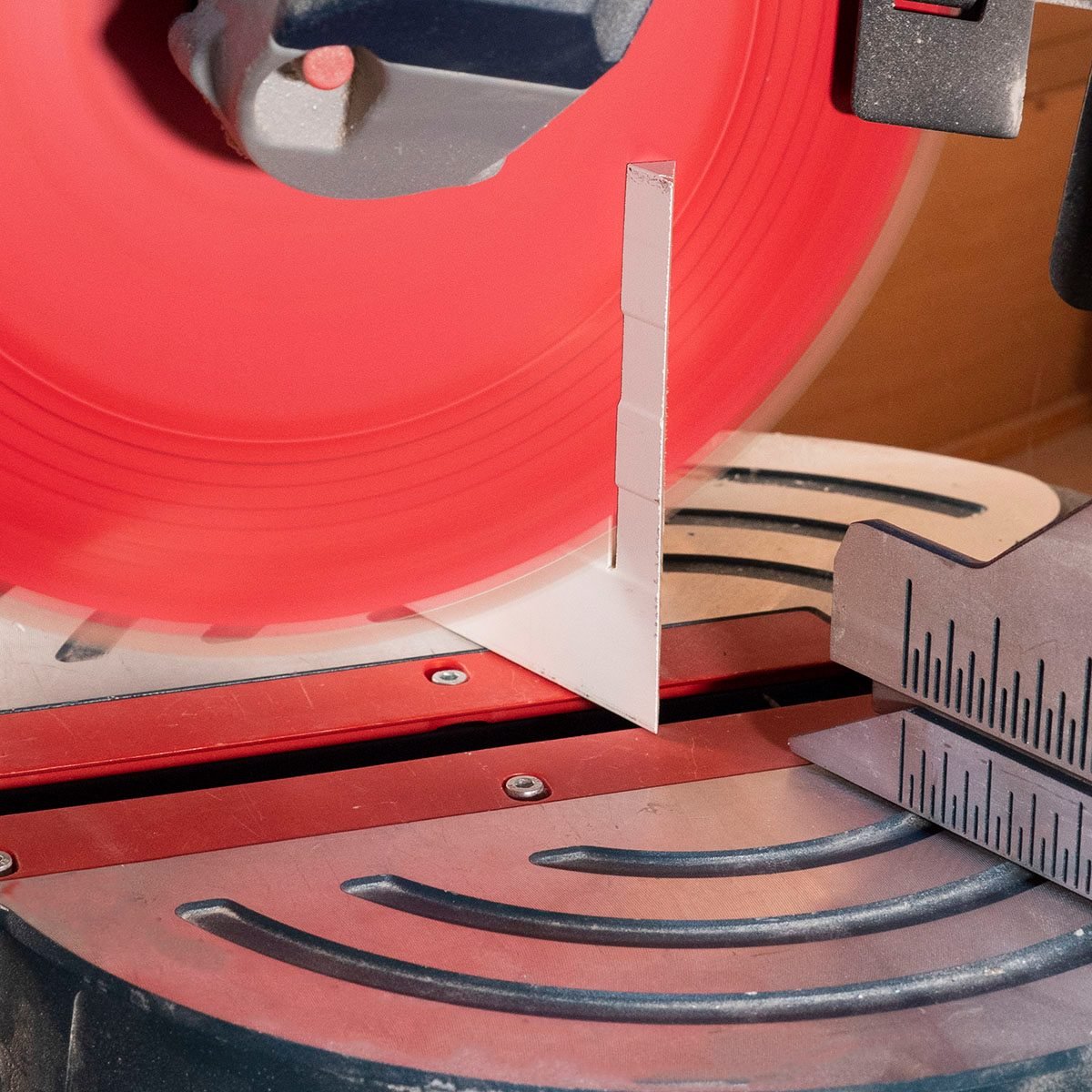

Set your miter saw at 45 degrees to the left. Now position the molding upright so the back is flat against the fence of your miter saw. Cut a 45-degree angle off the end of the baseboard.

Next, set your saw at 22-1/2 degrees and turn the molding upside down. Cut straight down and stop at the curvy part of the profile. Always cut the baseboard a couple of inches too long. You can cut it to the final length after the coping is done.

Now comes the fun part of cutting the cope.

First, make a few relief cuts to allow waste to fall away and your saw to make turns more easily. Carefully saw along the profile created by the miter cut using a coping saw. Angle the coping saw back about 30 degrees to remove more wood from the back of the molding. Concentrate on staying just outside the line. You can always sand or file away extra material.

Fine-tune the cope. Use files, rasps or sandpaper to clean up the cope cuts. Use a small half-round file for tight curves.

Pro tip: Glue a piece of 150-grit sandpaper to the face of a piece of scrap molding to get the exact contour of the profile.

No comments